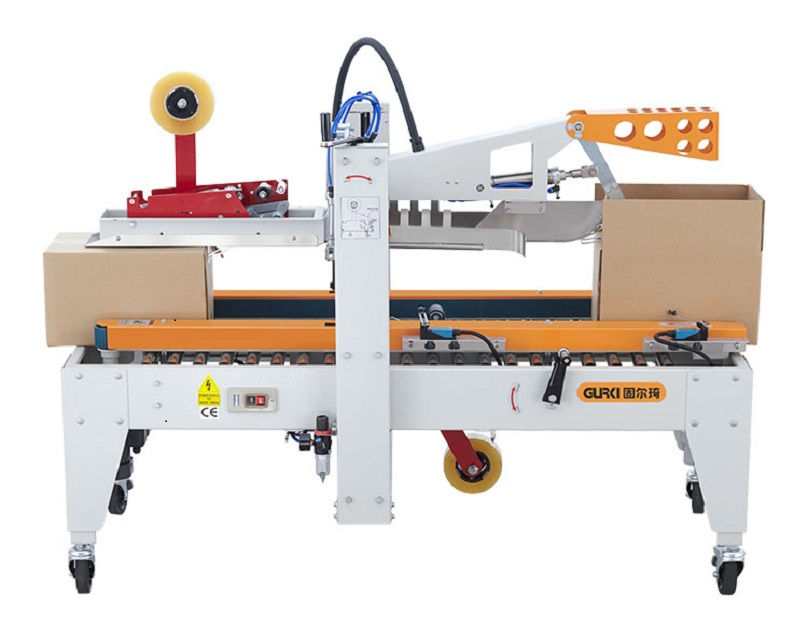

Best Automatic Carton Box Sealing Machine

- Jebat Seoh

- Jul 31, 2025

- 4 min read

Strong and smart packing keeps your products safe and ready to go. As work gets faster and more goods go out, businesses need tools that keep up. A carton sealer machine grips each box and seals it with care, saving time and cutting mistakes. It helps workers finish more boxes with less effort and keeps every carton neat. Whether you pack snacks, gadgets, or books, this machine makes packing smoother.

How It Enhances Packaging Efficiency

A sealing machine does more than close boxes. It lifts the entire packing process to a new level. With clean, tight seals, products travel more safely and look more professional.

Benefits You’ll Notice:

Boosts packing speed without errors

Cuts down on tape waste and manual labour

Reduces damage during shipping

Prevents loose seals that risk product loss

Fast, neat, and tough—this machine becomes the backbone of any packaging line.

How It Works in Real Time

Automatic sealing machines grip each box and push it through rollers. While moving, tape rolls apply pressure to seal the top and bottom flaps in one go. There’s no need for hand-taping or checking for loose edges.

What Happens Inside the Machine:

Cartons glide onto the entry platform

Guide rails align each box.

Rollers secure the tape firmly.

Finished boxes exit smoothly.

The machine repeats this with speed and accuracy, allowing lines to keep moving.

Sealing Matters in Automated Lines

Machines that pack and seal must work in harmony. When connected to a weighing filling machine, the sealer ensures the final touch is swift and spot-on. It locks in goods, adds a layer of protection, and supports high-volume tasks with ease.

Common Packaging Pairings:

Weighing and filling systems

Shrink tunnels and a wrap machine.

Label applicators for final branding

With everything in sync, the whole operation moves like clockwork.

What Makes a Good Carton Sealer

Not all machines deliver the same output. Some operate with fixed settings, while others allow fine adjustments. The best sealing machine fits your setup without slowing down your flow.

Signs of a Quality Machine:

Handles various box sizes without error

Maintains strong seals across long shifts

Works well with other packaging tools

Choose one that stays solid even under pressure.

Types of Carton Sealing Machines

Every setup demands a different solution. Some operations pack dozens of small boxes daily. Others send out bulkier cartons. That’s why sealing machines come in types to match every situation.

Manual and Semi-Automatic

These machines assist operators by holding boxes steady and applying tape. Workers still guide each carton through, but the device takes care of sealing.

Best for: Small businesses or lines with low-volume packing.

Fully Automatic

These units handle everything without hands-on help. They sense the box size, fold the flaps, and seal both ends. Just feed the carton in, and the machine takes care of the rest.

Best for: High-speed lines or industries with bulk packaging needs.

How to Choose the Right One

The right carton sealing machine depends on your packaging line. Some handle light boxes. Others grip heavier cartons with more force. Always match the machine to the box type and size. Look for tools that stay reliable even after long hours of use.

Key Factors to Consider:

Carton size and weight range

Sealing speed per minute

Manual vs. fully automatic systems

Stay alert to your line’s needs to pick a machine that fits snugly.

Integration with Other Equipment

A sealing machine shines when it works with other tools. It connects smoothly with the filling machine up front and the shrink wrap machine at the end.

Before the Sealer – Weighing and Filling

Goods must go into the carton accurately. A weighing filling machine ensures each box holds the right amount before moving on. This keeps the packaging even and cuts product loss.

What it adds:

Weight control

Precise filling

Uniform product distribution

After the Sealer – Shrink Wrapping

Once sealed, the box often passes through a shrink tunnel. A shrink wrap machine covers it in film, and then heat shrinks the film tightly around the box. This protects the product and boosts shelf appeal.

What it adds:

Moisture resistance

Tamper protection

A polished, finished look

Safety and Maintenance Tips

Like any machine, a carton sealer needs regular care. Keep it in top shape to avoid sudden breakdowns and keep operators safe.

Daily Practices

Wipe dust and debris from rollers.

Check for loose tape heads or parts.

Switch off the unit when idle.

Train staff on safe loading and unloading

Monthly Checks

Inspect belts and replace worn ones.

Check tape alignment

Tighten screws or fasteners.

Oil moving joints if needed

Simple habits keep machines reliable and last longer.

Who Should Use Carton Sealing Machines

These machines suit many industries that move goods in bulk or need consistent output. Whether you pack dry foods, electronics, or bottled items, sealing machines play a vital role.

Best-Fit Industries

E-commerce fulfilment centres

Electronics and gadget makers

Warehouses and distribution hubs

Food processing and packing plants

Do your work involves box packaging, this machine becomes a must-have.

Environmental Considerations

Sealing machines can also support eco-friendly practices. When used wisely, they help reduce tape usage, limit waste, and support recyclable materials.

Sustainable Choices:

Use recyclable packing tape

Adjust the tape length to avoid excess.

Choose machines with low power draw.

Set box sizes to match the contents

Smarter use leads to greener results—without slowing production.

Cartons Steady and Sealed Every Time

When your boxes slip or shift, sealing becomes messy. To avoid this, machines need a strong grip and balance. A well-built carton sealer machine holds every box firmly in place, no matter the size or weight. This keeps your tape lines clean and your products safe inside.

What Makes a Stable Seal:

Adjustable side rails to guide boxes straight

Steady rollers that move cartons without jerks

Press the arms to press the tape firmly.

A firm base to stop the carton from tilting or wobbling

Final Thoughts

Great packing starts with smart tools. A steady carton sealer machine grabs each box, sticks the tape tight, and rolls it down the line. It guards your goods, keeps the pace strong, and gives your boxes a clean finish. Add it beside filling tools and shrink wrappers to build a strong, fast-moving team. Pick one that fits your line, clean it often, and it’ll work hard for years. In every busy place, this machine helps your team seal each box right, every single time.

Comments