Who Supplies High-Quality Powder Filling Machines in Malaysia?

- Jebat Seoh

- Jan 14

- 4 min read

Many factories in Malaysia lose time and money because of poor powder filling. Bags leak. Weights change. Output slows down. These problems hurt trust and delay orders. As a result, manufacturers now look harder at the machines they use.

In 2026, demand for accurate and clean powder packing is higher than before. Food safety rules are strict. Labour costs keep rising. At the same time, buyers expect neat and even packs. Because of this, choosing the right powder filling machine in Kuala Lumpur matters more than ever.

This guide explains who supplies high-quality weighing filling machines in Malaysia today. It also shows what to look for, what to avoid, and why Auto Pak Trading Sdn Bhd remains a trusted name for many local manufacturers.

Why Powder Filling Machines Matter in 2026

actories now run on speed and trust. If a machine fails, production stops. If the weight varies, the products get rejected. Therefore, powder filling machines play a key role in daily work.

Many Malaysian businesses pack:

Milk powder

Spices and seasoning

Coffee and tea mixes

Protein and health powders

Chemical and cleaning powders

Each product behaves in a different way. Some flow well. Others stick or create dust. Because of this, machines must handle powder with care and control.

Also, buyers now expect clear labels and exact weight. So accuracy is no longer optional.

What Makes a High-Quality Powder Filling Machine

Not every machine suits every factory. Still, good machines share a few clear traits.

Strong Accuracy Control

A reliable weighing filling machine in Malaysia keeps the same weight for each pack. This helps avoid loss and waste. It also protects brand trust.

Solid Machine Build

Good machines use stainless steel parts. Frames stay firm during use. Panels resist rust and heat. This matters in humid factory spaces.

Easy Operation

Operators should understand the system fast. Simple screens and clear buttons help reduce errors. Because of this, training time stays low.

Easy Cleaning

Powder builds up fast. Machines must allow easy access for cleaning. This helps meet food and safety rules.

Local Service Support

Even strong machines need care. Local service teams reduce downtime. Spare parts must be easy to get.

Types of Powder Filling Machines Used in Malaysia

Before choosing a supplier, it helps to know the main machine types.

Auger Powder Filling Machines

These machines use a rotating screw to fill powder. They suit fine powders like flour, spices, and milk powder. Many food factories use this type.

Weighing Powder Filling Machines

These machines fill based on weight, not volume. They give higher accuracy. As a result, they suit products sold by exact weight.

Semi-Automatic Machines

Small and medium factories often use these. Operators place the pack by hand. The machine fills it.

Fully Automatic Machines

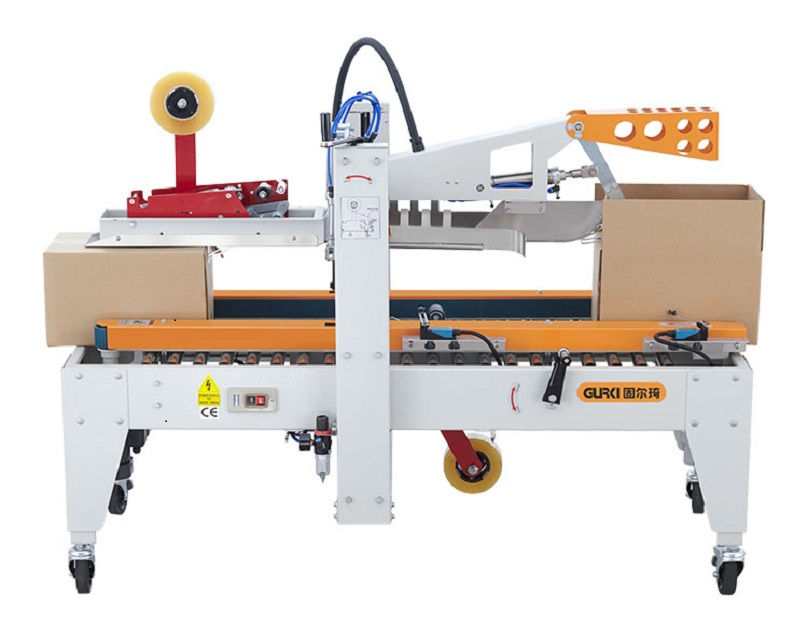

Large factories use full systems. These include conveyors, fillers, and sealers. They support high output with less labour.

Auto Pak Trading Sdn Bhd supplies all these types, based on real production needs.

Powder Filling Machine in Kuala Lumpur: Local Factory Needs

Factories in Kuala Lumpur face space limits. At the same time, they run long shifts. Because of this, machines must fit well and work without pause.

Local buyers often look for:

Compact machine design

Stable output during long hours

Low dust release

Fast local service

Suppliers who understand local factory layouts can offer better solutions. This helps avoid costly changes later.

Who Supplies Powder Filling Machines in Malaysia in 2026?

Several suppliers operate in Malaysia. However, only a few meet modern factory needs.

Auto Pak Trading Sdn Bhd

Auto Pak Trading Sdn Bhd stands out as a trusted supplier of powder filling machines in Malaysia. Many factories in Kuala Lumpur and beyond rely on their systems.

The company focuses on machine performance, not just appearance. Their solutions suit food, chemical, and health product makers.

Key strengths include:

Accurate weighing filling machine Malaysia options

Machines matched to powder type

Local technical support

Spare parts stocked in Malaysia

Clear guidance before purchase

Because of this, many buyers stay with them for years.

Why Manufacturers Choose Auto Pak Trading Sdn Bhd

Trust grows through results. Auto Pak Trading Sdn Bhd earns trust through steady output and strong service.

Real Industry Experience

The team understands powder behaviour. This helps avoid common issues such as clogging or uneven fills.

Proper Machine Testing

Machines are tested before delivery. This reduces setup problems and saves time after installation.

Honest Advice

Buyers receive guidance based on output goals and budget. The focus stays on long-term value.

Local After-Sales Support

Local technicians handle setup, training, and repair. This helps keep production moving.

Conclusion

Choosing a powder filling machine in Kuala Lumpur in 2026 is a key business decision. Accuracy, build quality, and service support now matter more than ever. As factories grow and standards rise, weak machines cause delays and loss.

Auto Pak Trading Sdn Bhd continues to support Malaysian manufacturers with reliable powder filling and weighing solutions. Their focus on accuracy, local service, and long-term value makes them a trusted supplier across many industries. For businesses that value steady output and fewer problems, working with an experienced local supplier remains a smart choice.

FAQs

What is the best powder filling machine in Malaysia?

The best machine depends on powder type, pack size, and output needs. Many manufacturers choose systems supplied by Auto Pak Trading Sdn Bhd for reliability and local support.

Are weighing filling machines more accurate than auger fillers?

Yes. Weighing filling machines measure actual product weight, which improves accuracy and reduces overfill, especially for high-value powders.

Can powder filling machines handle fine and dusty products?

Modern machines include dust control features. Proper auger design and sealing help manage fine powders safely.

Why buy from a local supplier in Kuala Lumpur?

Local suppliers offer faster service, easier spare parts access, and a better understanding of Malaysian factory conditions.

Comments